-

Hello there guest and Welcome to Modular Fox Mustangs home of the 2V, 3V, 4V, Coyote Modular Mustang Conversion Information Website!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Teksid 2V Tech Article (Must Read)

- Thread starter ModFoxMustangs

- Start date

I think the last one I did used a relocation fitting. I do not believe that bracket is structural. The rib behind it is, but I think you might be able to cut/sand enough off of the part that is in the way to get the switch in place.

Thanks Bill,

I'll see if I can find a used relocation fitting before the engine is ready to go back in. If not, I'll notch that part to make room for the switch

Hi Taylor,

Thanks for reaching out. It sounds like you have a really nice build going. I think the Tbird front cover will fit fine with the Windsor heads. Don't forget that it actually came on a lot of different applications, so don't let the salvage yards charge you "Thunderbird" pricing. Your Windsor heads will also be fine. Given the amount of work you already have in them, they should make great power. I really like the Cobra Engineering link you posted. I love that fixture and those pins look sweet. The fact that they are using stress relieved steel to manufacture them speaks to the amount of experience they have with the product. It has been a while, it seems like the cost of that fixture is about what the machine shop charged me the last time I assembled one. Moving to a one piece lower sprocket is a good call for your application. I know the technology has improved since I sold my shop, but that seems to be the way to go still. If you haven't already, you should check out this guy's stuff: https://www.youtube.com/user/andrewlavender08/videos?disable_polymer=1. He makes more power than I ever even tried to make. As far as a valve recommendation, I'm afraid I'm out of date on that one. I always used Ford Racing 2V guides on these builds, but I didn't have 9mm pins available. Some of the new polymer guide technology is looking pretty good. I'm glad you have a conservative tuner. I agree that (depending on your chassis loss) he probably could have pulled close to 600 out of that on the bleeding edge. An impressive dyno sheet is fun to show off, but not worth much after the engine has a highspeed come-apart. I would really love to watch your build take shape. If you have time, please start a build thread and post up some pictures and tell us about lessons learned. And remember, question everything.

Wow!!!

I am new to this site, took my time to read this entire post and am now on moduler overload. I have a problem that kind of goes along this line and feedback would be appreciated. I am not new to the Mustang world on the contrary this is my 5th pony but the 1st with a modular motor. I purchased a real peach. Southern GT convertible in perfect shape. No rust, no hits, new top, 2004 in screaming yellow (I guess only 212 made that year) the motor is a 4.6 SOHC 2v. It has had some tuning done, intake improvement, very nice cat-back exhaust. It dynos out at about 340hp. It really is a spunky little motor and a load of fun to drive. I have a set of Ford Racing PI aluminum heads with cams that I was going to put on her and probably squeeze another 40 or 50 hp out of it but then ran into a deal I could not refuse. A 1988 Lincoln Mark VIIl Teksid 4v 73000+miles and the AOD transmission for $200. Needless to say I could not turn it down. I was thinking of doing a rebuild on this and replace the 2v but is it worth it given the amount of work I will have to do to the convertible (stiffer frame rails, torque boxes, etc) to handle 600+ hp in stead of bending the car all up. My question is would it be worth it? What would you do? Your answers may convince me one way or another.

Look forward to your answer,

Scott owner of the “GTEEUP” project

I am new to this site, took my time to read this entire post and am now on moduler overload. I have a problem that kind of goes along this line and feedback would be appreciated. I am not new to the Mustang world on the contrary this is my 5th pony but the 1st with a modular motor. I purchased a real peach. Southern GT convertible in perfect shape. No rust, no hits, new top, 2004 in screaming yellow (I guess only 212 made that year) the motor is a 4.6 SOHC 2v. It has had some tuning done, intake improvement, very nice cat-back exhaust. It dynos out at about 340hp. It really is a spunky little motor and a load of fun to drive. I have a set of Ford Racing PI aluminum heads with cams that I was going to put on her and probably squeeze another 40 or 50 hp out of it but then ran into a deal I could not refuse. A 1988 Lincoln Mark VIIl Teksid 4v 73000+miles and the AOD transmission for $200. Needless to say I could not turn it down. I was thinking of doing a rebuild on this and replace the 2v but is it worth it given the amount of work I will have to do to the convertible (stiffer frame rails, torque boxes, etc) to handle 600+ hp in stead of bending the car all up. My question is would it be worth it? What would you do? Your answers may convince me one way or another.

Look forward to your answer,

Scott owner of the “GTEEUP” project

Attachments

Scottie, if the dyno says you have 340 at the wheels, you've got a pretty outstanding 4.6 2v already. Maybe do some suspension work to make that horse really prance? Check out coilover conversions for the front, a panhard bar for the back, and quality dampers all around, you'll like the effect on handling.

...regards, kevin

...regards, kevin

So, i'm degreeing the cams, and i've noticed an alarming future oil leak where the heads meet the block, just behind the timing cover. I'm attaching photos for everyones' entertainment. Because the 2v heads are identical, all you have to do is plug or unplug oil passage holes to use them on left or right sides. When you place the head gaskets, if you're a clueless newbie like me and don't think ahead, you can fit them perfectly wrong, as in the front of the gasket at the back of the head... and they fit. Then when you've torqued the heads down, installed the cams and torqued the cam girdles, and put on the timing gears and chains you notice that you've taken one step forward and need to take two steps back

Question: should i just get a new set of head gaskets, or can i just reposition these? If any of you feel like using cuss words on my behalf, i'd appreciate it because i'm running out. ...regards, kevin

Question: should i just get a new set of head gaskets, or can i just reposition these? If any of you feel like using cuss words on my behalf, i'd appreciate it because i'm running out. ...regards, kevin

Attachments

Scottie, if the dyno says you have 340 at the wheels, you've got a pretty outstanding 4.6 2v already. Maybe do some suspension work to make that horse really prance? Check out coilover conversions for the front, a panhard bar for the back, and quality dampers all around, you'll like the effect on handling.

...regards, kevin

[/QUOTE

Hey K, I really appreciate your input. I should have mentioned in my post that I already upgraded the dampeners, struts, all the rubber as well as all the tie rods, ball joints, sway bar links, etc, etc. basically if it had dirt on it it got replaced. The only thing left to do as you stated coil overs and a pan hard in the rear would be a great upgrade. What I’m thinking is given that this is a drop top it does not have the support a topped Mustang has. It is great for cruising with your girl on a sunny afternoon but taking four or five passes at my favorite track causes the doors to go out of adjustment. Boxing in the frame rails is on the agenda and maybe some work on the torque boxes will illuminate these problems and maybe help if I decide on a 4v monster. I’m just throwing it out there if anyone would go there Teksid 4v route and is it worth it or am I just opening Pandora’s box of problems.Scottie, if the dyno says you have 340 at the wheels, you've got a pretty outstanding 4.6 2v already. Maybe do some suspension work to make that horse really prance? Check out coilover conversions for the front, a panhard bar for the back, and quality dampers all around, you'll like the effect on handling.

...regards, kevin

Don't feel bad, I've seen pros put one on backwards. It's Murphy's Law. If it were me, I would likely just get a new set of gaskets. As for the lovely little gap, the Ford Service Manual for the 2valve engines assembly shows a handful of places like that where the factory sealed it with a small amount of silicon.So, i'm degreeing the cams, and i've noticed an alarming future oil leak where the heads meet the block, just behind the timing cover. I'm attaching photos for everyones' entertainment. Because the 2v heads are identical, all you have to do is plug or unplug oil passage holes to use them on left or right sides. When you place the head gaskets, if you're a clueless newbie like me and don't think ahead, you can fit them perfectly wrong, as in the front of the gasket at the back of the head... and they fit. Then when you've torqued the heads down, installed the cams and torqued the cam girdles, and put on the timing gears and chains you notice that you've taken one step forward and need to take two steps back

Question: should i just get a new set of head gaskets, or can i just reposition these? If any of you feel like using cuss words on my behalf, i'd appreciate it because i'm running out. ...regards, kevin

Welcome to the party. That is a beautiful machine. I have an 04 GT Vert also and love it. If you are going to 600 rwhp, regardless of the power plant, I suggest calling Brian Figg over at Stifflers and get a nice slide-to-fit matrix setup. The cost is relatively low for what you get and it will stiffen that chassis right up and keep it nice and square.Wow!!!

I am new to this site, took my time to read this entire post and am now on moduler overload. I have a problem that kind of goes along this line and feedback would be appreciated. I am not new to the Mustang world on the contrary this is my 5th pony but the 1st with a modular motor. I purchased a real peach. Southern GT convertible in perfect shape. No rust, no hits, new top, 2004 in screaming yellow (I guess only 212 made that year) the motor is a 4.6 SOHC 2v. It has had some tuning done, intake improvement, very nice cat-back exhaust. It dynos out at about 340hp. It really is a spunky little motor and a load of fun to drive. I have a set of Ford Racing PI aluminum heads with cams that I was going to put on her and probably squeeze another 40 or 50 hp out of it but then ran into a deal I could not refuse. A 1988 Lincoln Mark VIIl Teksid 4v 73000+miles and the AOD transmission for $200. Needless to say I could not turn it down. I was thinking of doing a rebuild on this and replace the 2v but is it worth it given the amount of work I will have to do to the convertible (stiffer frame rails, torque boxes, etc) to handle 600+ hp in stead of bending the car all up. My question is would it be worth it? What would you do? Your answers may convince me one way or another.

Look forward to your answer,

Scott owner of the “GTEEUP” project

Bill hit it on the head, stiffen the chassis. The '04 convertible has factory bolt-on subframe connectors, which do little to stiffen the chassis. I welded in full length subframe connectors (which are also bolted to the floorpan using the rear bolts of the front seats), and i noticed the difference immediately. The car felt more "planted", likely a combination of anchoring the seats more securely and properly (don't look too closely at my welding) connecting the front and rear subframes. Nice score, by the way. You don't see many really nice non-cobra New Edge GT's these days, but you found one!

Here's a photo of those perfectly wrongly placed gaskets. Yes, Mr. Murphy visits here regularly. On a positive note, i checked the Fel-Pro site and discovered that MLS gaskets can be cold-torqued more than once (to check for PTV clearance, for instance). They can't be reused after the engine has been run, because heat makes the layers bond together. You learn something every day, whether you want to or not...

I'm attaching a picture of the porting i did on the intake manifold as well. Just a tapered port-match, with emphasis on the long-side radius.

...regards, kevin

Here's a photo of those perfectly wrongly placed gaskets. Yes, Mr. Murphy visits here regularly. On a positive note, i checked the Fel-Pro site and discovered that MLS gaskets can be cold-torqued more than once (to check for PTV clearance, for instance). They can't be reused after the engine has been run, because heat makes the layers bond together. You learn something every day, whether you want to or not...

I'm attaching a picture of the porting i did on the intake manifold as well. Just a tapered port-match, with emphasis on the long-side radius.

...regards, kevin

Attachments

Thank you! I will do just that!Welcome to the party. That is a beautiful machine. I have an 04 GT Vert also and love it. If you are going to 600 rwhp, regardless of the power plant, I suggest calling Brian Figg over at Stifflers and get a nice slide-to-fit matrix setup. The cost is relatively low for what you get and it will stiffen that chassis right up and keep it nice and square.

I always thought that an additional hole needed to be drilled when putting 2v heads on a Teksid block for cooling?

2v intake flows coolant through it, 4v does not

Also those gaps look kinda big. Just going from my experience. Yes RTV goes where the cover meets the heads and where cover meets oil pan. But usually the gap is very slight.

2v intake flows coolant through it, 4v does not

Also those gaps look kinda big. Just going from my experience. Yes RTV goes where the cover meets the heads and where cover meets oil pan. But usually the gap is very slight.

Last edited:

I included a photo in post #37 of the hole i drilled for the Romeo cooling passage. I'm flattered that it looks so... factory that you didn't see itAs for the gaps, once i put the gaskets on correctly, they magically disappeared! ...regards, kevin

Nice! Glad you got it figured out

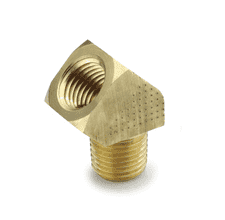

This thread came to mind last night as I was modifying a 2V PI manifold to use a 97GT wiring harness. I haven't asked what harness you are using. I like the pre-PI harness because it has two temp sensors, including one very close to the hole that gets drilled in the block. It came to mind that I had seen one using a PI harness, where the builder made the modification to add the second temp sensor, but plugged the original hole and put the single sensor on the driver side right next to the thermostat. He did it because he wanted to make sure the temp sensor was close to the point of potential heat issues. I put this in my own build book for the next one I do, as I thought it would be a good engineering practice. On my current project, I noted that the manifold is nice and thick there on that flat boss next to the thermostat, so the hole is very sturdy. I drilled in multiple steps but ended with a 37/64" drill bit and used a 3/8 NPT tap. Edit - in rereading this post, I need to dig the tap and drill bit out. The numbers don't add up and I want to see what I actually used. As I always preach, question everything.I included a photo in post #37 of the hole i drilled for the Romeo cooling passage. I'm flattered that it looks so... factory that you didn't see itAs for the gaps, once i put the gaskets on correctly, they magically disappeared! ...regards, kevin

Last edited:

Good suggestion. I'm using the factory wiring for my '04 GT, but it's easy to solder in an extension on the temp. sensor. It's almost like Ford left the option open to put a sensor next to the thermostat on the PI intake manifold (photo included).

I have a question about cams: I'm using COMP XE262AH cams, and after setting them "straight up" (crank at TDC, timing marks aligned on the chains and gears), i measured the intake centerline on cylinders 6 and 1, and i came up with a 103 degree centerline on both banks. The cam card says the intake centreline is 109 degrees, so it looks like the cams are 6 degrees advanced at "straight up". I have adjustable crank gears. Should i retard the cams 6 degrees? From what i've read, COMP (and most other cam manufacturers) grind 4 degrees advance into their cams, so i don't want my valves opening too soon. These cams are pretty mild, and there shouldn't be a PTV clearance issue, but still...

...regards, kevin

just because you're paranoid, it doesn't mean they're not all out to get you...

I have a question about cams: I'm using COMP XE262AH cams, and after setting them "straight up" (crank at TDC, timing marks aligned on the chains and gears), i measured the intake centerline on cylinders 6 and 1, and i came up with a 103 degree centerline on both banks. The cam card says the intake centreline is 109 degrees, so it looks like the cams are 6 degrees advanced at "straight up". I have adjustable crank gears. Should i retard the cams 6 degrees? From what i've read, COMP (and most other cam manufacturers) grind 4 degrees advance into their cams, so i don't want my valves opening too soon. These cams are pretty mild, and there shouldn't be a PTV clearance issue, but still...

...regards, kevin

just because you're paranoid, it doesn't mean they're not all out to get you...

Attachments

Agreed. That aluminum is really thick there. I used a 37/64th bit and a 3/8 NPT tap. It is tight, but it went in okay. EDIT - One of the faction sizes is off. I will have to dig the set out and see which oneGood suggestion. I'm using the factory wiring for my '04 GT, but it's easy to solder in an extension on the temp. sensor. It's almost like Ford left the option open to put a sensor next to the thermostat on the PI intake manifold (photo included).

I also agree that you should discuss it with a cam engineer at Comp Cams. The last time I called them was for a "big matha' thumper" I was installing...what a hoot that was. I got schooled on all of my bad habits.

https://www.compcams.com/contact-us

Last edited:

After pulling apart, putting together, changing timing, using modelling clay and measuring PTV clearance about 12 times, i've found that the closest i can get the intake centerline is 111 degrees (cam cards want 109 degrees intake centerline). Measuring PTV clearance at 2 degree intervals starting at 4 degrees BTDC, i find that the tightest gap between the intake valve and the #6 piston is at 8 degrees ATDC, and it's a bit too close at .028". I called COMP cams, and the tech said i should aim for at least .060" clearance on the intake and .080" on the exhaust. It looks like i'm going to have to machine valve reliefs into the pistons to get those numbers. One step forward. at least 2 steps back... Pistons have to come out for machine work...  On a positive note, i'm getting better at tearing the heads apart! ...regards, kevin

On a positive note, i'm getting better at tearing the heads apart! ...regards, kevin